Supplier sections

Rate this page

Ultra-high-efficiency 76V DC/DC Buck converter from ROHM

Provides high reliability and greater energy savings ideal for communications infrastructure and industrial equipment

Provides high reliability and greater energy savings ideal for communications infrastructure and industrial equipment

ROHM has announced the availability of a 12 to 76V input, 3A variable output voltage, DC/DC Buck converter with integrated 76V MOSFET optimized for high power (high voltage x large current) applications such as motors, factory automation equipment, communications infrastructure, and industrial machinery.

In recent years, with the increasing importance to conserve energy in all areas comes a push to achieve greater energy savings - even in the industrial equipment sector - through the use of high power semiconductor devices and power supply ICs. And with this comes a need to provide breakdown voltages higher than the input voltage to prevent damage due to instantaneous surge and transient voltages (such as those caused by lightning).

In response, ROHM leverages its advanced cutting-edge power processes and vertically-integrated production system to develop products for the industrial equipment market that demands long-term, stable supply along with high reliability to enable continuous operation.

The BD9G341AEFJ utilizes ROHM's high voltage 0.6um BiCDMOS process to achieve an industry-leading maximum breakdown voltage of 80V (the highest in ROHM's non-isolated DC/DC converter lineup) and a continuous operating input range of 12 to 76V, while market-proven advanced analog design technology results in the highest conversion efficiency in its class. In addition, multiple protection circuits minimize heat generation, even during output pin shorts (contact), preventing possible damage and increasing reliability vs. conventional products. And the compact 8pin package requires fewer parts and reduces mounting area, contributing to easier PCB placement and end-product miniaturization.

ROHM Buck DC/DC Converter Lineup BD9G341AEF Advantages

Key Features

Class-leading 76V breakdown voltage

Cutting-edge 0.6um high voltage BiCDMOS processes are utilized to develop a non-isolated DC/DC buck converter with an integrated MOSFET featuring the industry's highest maximum breakdown voltage in its class. As a result, support for input voltages up to 80V (max.) and 76V (operation) is provided, ensuring sufficient margin against sudden surge voltages in communication infrastructure, factory automation equipment, industrial machinery, and other applications that normally operate at 48V and higher, improving system reliability.

The industry's highest efficiency

The industry's highest power conversion efficiency in the 76V DC/DC converter class has been achieved by leveraging advanced market-proven analog design technology. Efficiency is increased by 1.5% compared to conventional products during stable operation and by as much as 19% (300kHz oscillation frequency, 48V supply, 5V output), improving energy savings in industrial equipment.

Output pin protection prevents damage for improved reliability

Conventional protection functions normally cannot suppress heat generation during output shorts (contact), which can lead to overheating and even damage. In contrast, ROHM's proprietary protection function minimizes heat generation during accidental output shorts, preventing damage and improving system reliability.

Compact package reduces mounting area and requires fewer external parts

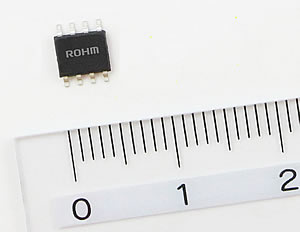

The BD9G341AEFJ is offered in a compact 8pin package (4.9mm x 6.0mm, t=1.0mm) and features a highly integrated design that reduces the number of parts required from 17 to 12, simplifying end-product design, BoM costs, and development efforts. High efficiency design improves energy savings Proprietary protection circuit increases reliability.

Applications

- Communication infrastructure such as switching and base stations, office telephone systems, routers, and other equipment requiring 48V input.

- Motor devices exposed to high surge voltages (e.g. electric bicycles, vacuum cleaners, industrial controllers).

For more information, or details on the full range of Rohm products available from Anglia, please email info@anglia.com

This news article was originally published in January 2016.