Supplier sections

Rate this page

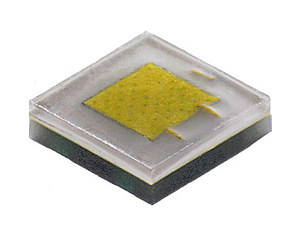

Cree's new high-intensity class of LEDs more than doubles performance

Cree has announced the new XLamp® XP-L High Intensity LED, the first single-die LED to deliver over 100,000 candelas with a 50-mm diameter optic at 10 watts. Built on Cree's breakthrough SC5 Technology™ Platform, the XP-L High-Intensity LED delivers more than double the candelas of the industry's previous highest-performing single-die XP-L LED through the same optic. Leveraging the existing 3.45-mm x 3.45-mm XP-L package, the new high-intensity LEDs allow lighting manufacturers to quickly boost performance, reduce size and lower system cost for applications such as track, outdoor and stadium lighting.

XLamp XP-L High-Intensity LED featuring Cree's innovative new primary optic design that radically reduces optical source size by more than 50 percent, the XLamp XP-L High Intensity LED delivers unprecedented candela at 185 lumens per watt at one watt. The new High Intensity LED offers a drop-in ready upgrade for XP-based luminaire designs, enabling manufacturers to achieve higher luminous intensity with minimal redesign to accelerate time to market.

"The XP-L High Intensity LED exemplifies Cree's commitment to relentless innovation by delivering both lumens and unprecedented intensity in a small form factor," said Dave Emerson, vice president and general manager for Cree LEDs. "The XP-L High Intensity LED will allow lighting designers to fundamentally change the way they think about using LEDs in high intensity lighting and enable lighting manufacturers to reach performance levels previously not possible."

Characterized and binned at 1050 mA, 85°C, the XP-L High Intensity LED is available in up to 90 CRI and color temperatures ranging from 2700 K to 8300 K. 6,000 hours of LM-80 long-term testing data is available for the XP-L High Intensity LED for lighting manufacturers seeking ENERGY STAR® qualification.

For more information, or details on the full range of Cree products available from Anglia, please email info@anglia.com

This news article was originally published in May 2016.